Blog

October 30, 2020

Spatial Gemba Walks: The next big thing for factory insights

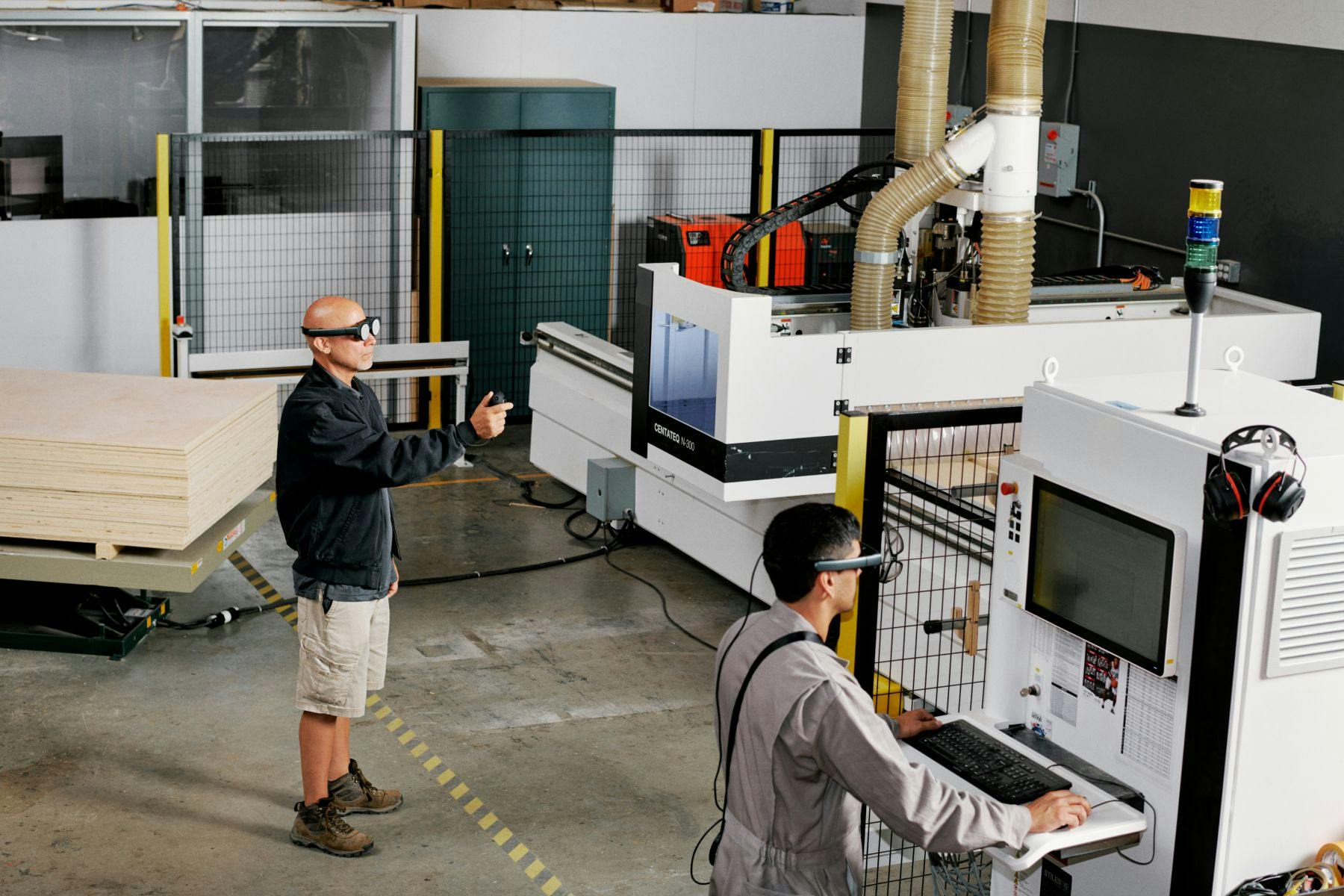

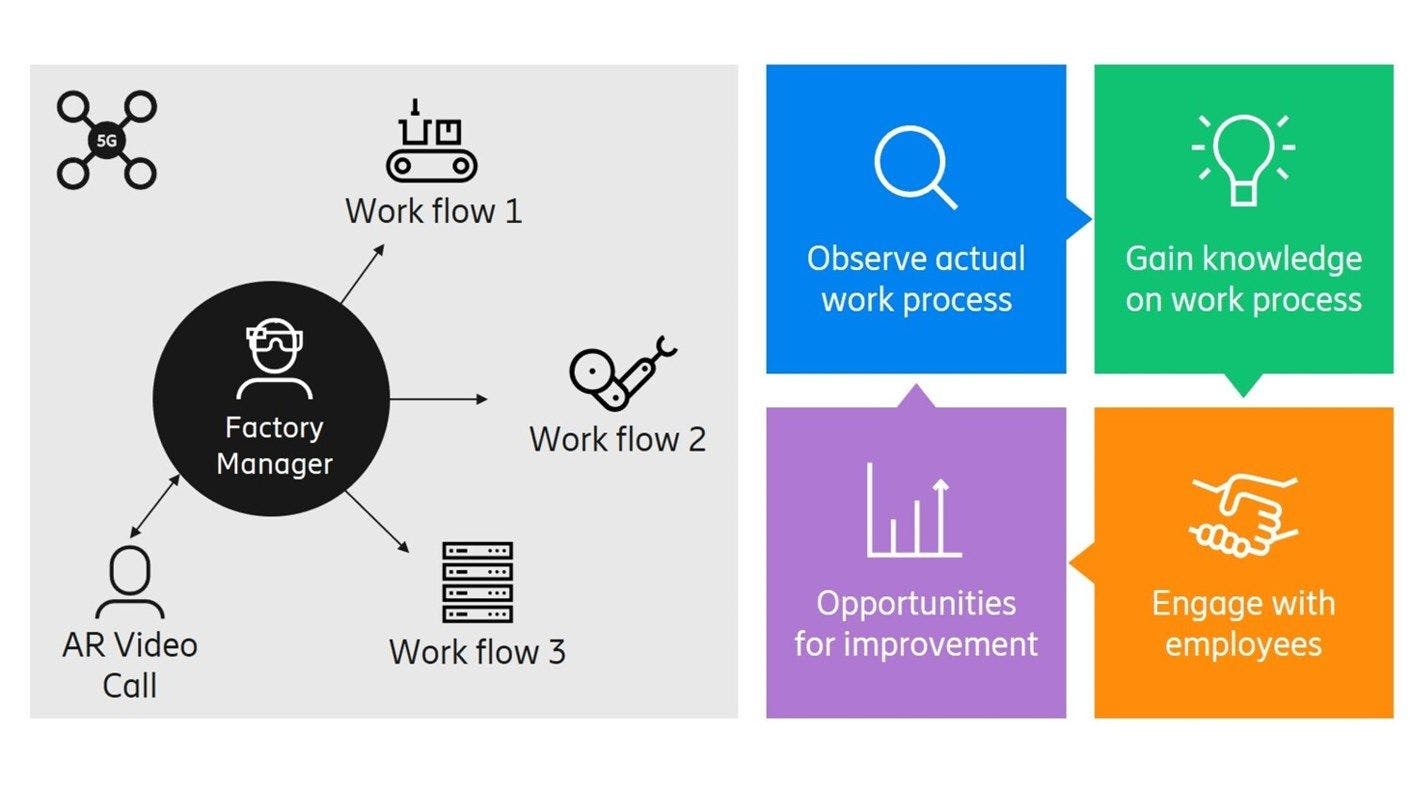

Within lean production, a factory manager takes regular Gemba walks on the factory floor to learn how the factory performs and develop ideas for how to improve it. Ericsson, a technology leader in 5G, explored how Magic Leap 1 and 5G can transform traditional Gemba walks, increasing efficiency and collaboration.

Gemba walks, a term of Japanese origin, are daily tours that factory managers perform on a factory floor to gain knowledge in work processes and to engage directly with employees. Gemba walks are rather dynamic, and managers can freely move and interact with the environment.

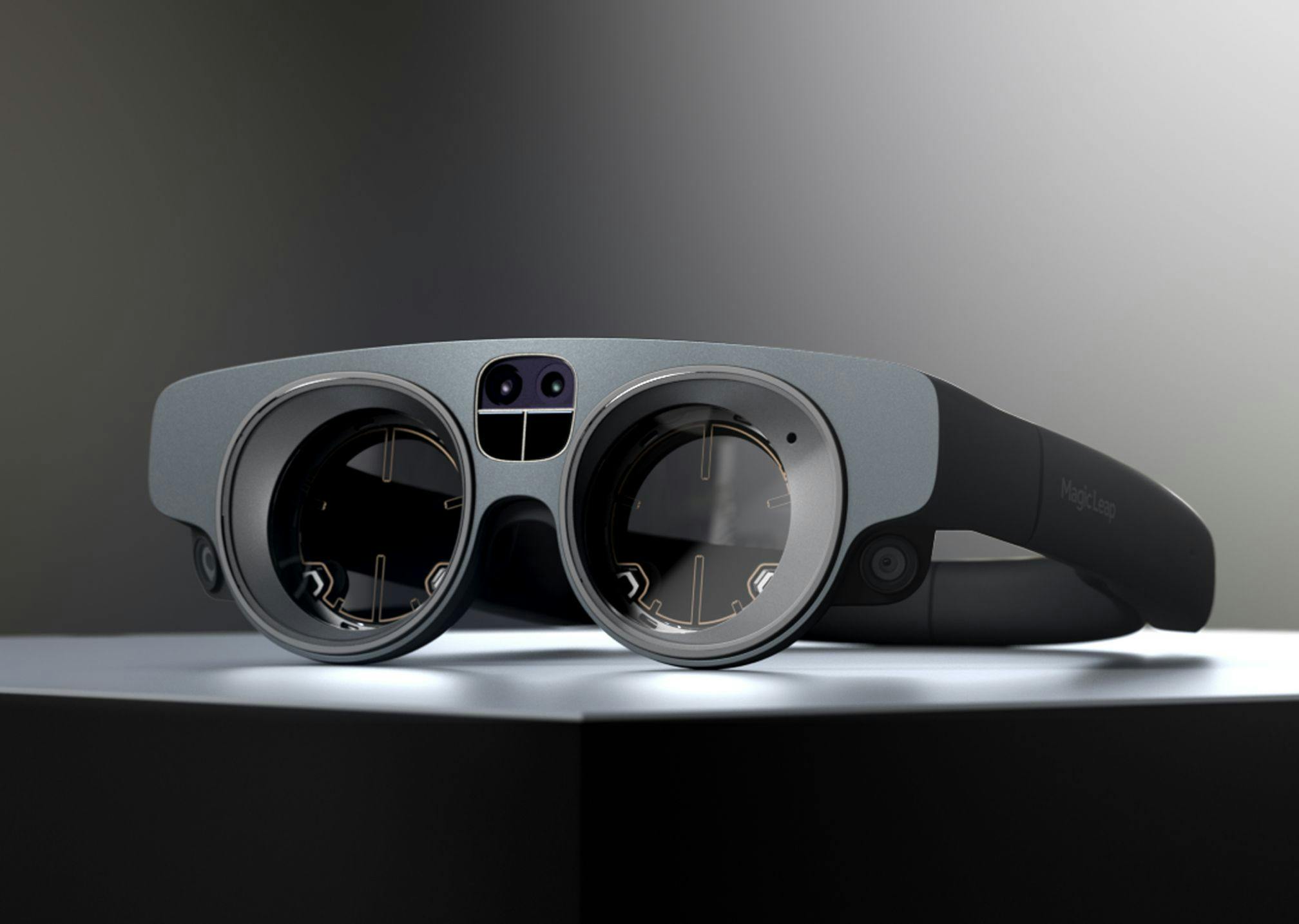

As the technology leader in 5G, Ericsson wanted to explore how Gemba walks could be enhanced with Augmented Reality and 5G connectivity. To develop and test a prototype that brings connectivity and data visualization to smart factories, they chose the Magic Leap 1 because of its robust capabilities in the industrial sector.

The result: Using Magic Leap 1 with 5G connectivity enabled by Ericsson, factory managers can get updated and receive context-relevant overlays of the factory’s digital data during the walk. Factory managers can also make a spatial audio and video call from the Magic Leap 1 they’re wearing to immediately reach out, share information and collaborate with experts inside and outside the factory.

Why do factories need to go spatial?

Today, digital twins are driving the transformation of physical factories, where every single object is digitally represented. Backend systems are rich with data such as resource planning, analytics, and shop floor performance sheets. As smart factories evolve to Industry 4.0, much more digital data is produced. Such data is enabling the speed-up of factory production, early detection of anomalies and faster troubleshooting. Spatial technology fits well with the digitization journey of industries, as it allows the simplification of digital data in form of overlays which are presented to the user on top of the real world. The data overlays match well with human cognition as people excel at making conclusions for visual expressions.

5G will play a central role in smart factories for a seamless Gemba walk experience on the factory floor, enabling connectivity, accurate localization of the machines and fast access to data. The deployment of 5G networks inside the factory provides reliable wireless coverage and secure low-latency communication from edge clouds to the AR device. In a nutshell, a connected spatial headset provides key insights and digital data to the factory manager, anytime, from anywhere.

The spatial Gemba walk

The Gemba walk starts with Bob, a factory manager, wearing his Magic Leap 1 headset while walking around the factory floor to review and learn how each workflow is contributing to the production process. The Magic Leap 1 is connected to 5G through a hotspot.

As Bob approaches a machine, key indicators, such as the overall equipment efficiency (OEE) of the machine is displayed on his Magic Leap 1. Bob can additionally browse detailed data sheets of the machine. For example, performance sheets are delivered, when requested, in real-time from the backend system over the deployed 5G network and rendered on Bob’s Magic Leap 1. The user interface is customizable and can be adapted to a specific use case or application.

Bob initiates an audio and video call within the Magic Leap 1 with Alice, the remote expert who is responsible for the machine. Bob selects the right contact from a personalized list of contacts associated with the machine. Pressing a video call button opens a conversational and data communication channel in a spatial web browser window.

During the call, Alice can see the real machine and answer Bob’s questions. Bob can switch back to the factory data visualization view after finishing the call with Alice.

The 5G Gemba walk future journey

5G Gemba walks present an opportunity for smart factories to leverage mobile and spatial technologies for understanding and increasing the efficiency of the production workflows. This technology opens up possibilities beyond today’s first wave of training to support AR use cases.

Including AR data visualization in the production process is just a first step to exploiting the value of digitalization in Industry 4.0. Partners like Ericsson and Magic Leap are leading the way toward the spatial transformation of manufacturing.

Latest Content

Blog

April 22, 2024

Improve precision and efficiency with Magic Leap 2 for AEC

Blog

April 2, 2024

Enhance manufacturing productivity and operational excellence with Magic Leap 2

News

March 25, 2024

NVIDIA IGX + Magic Leap 2 XR Bundle Now Available

Blog

March 22, 2024